Iyini i-IXPE/PP

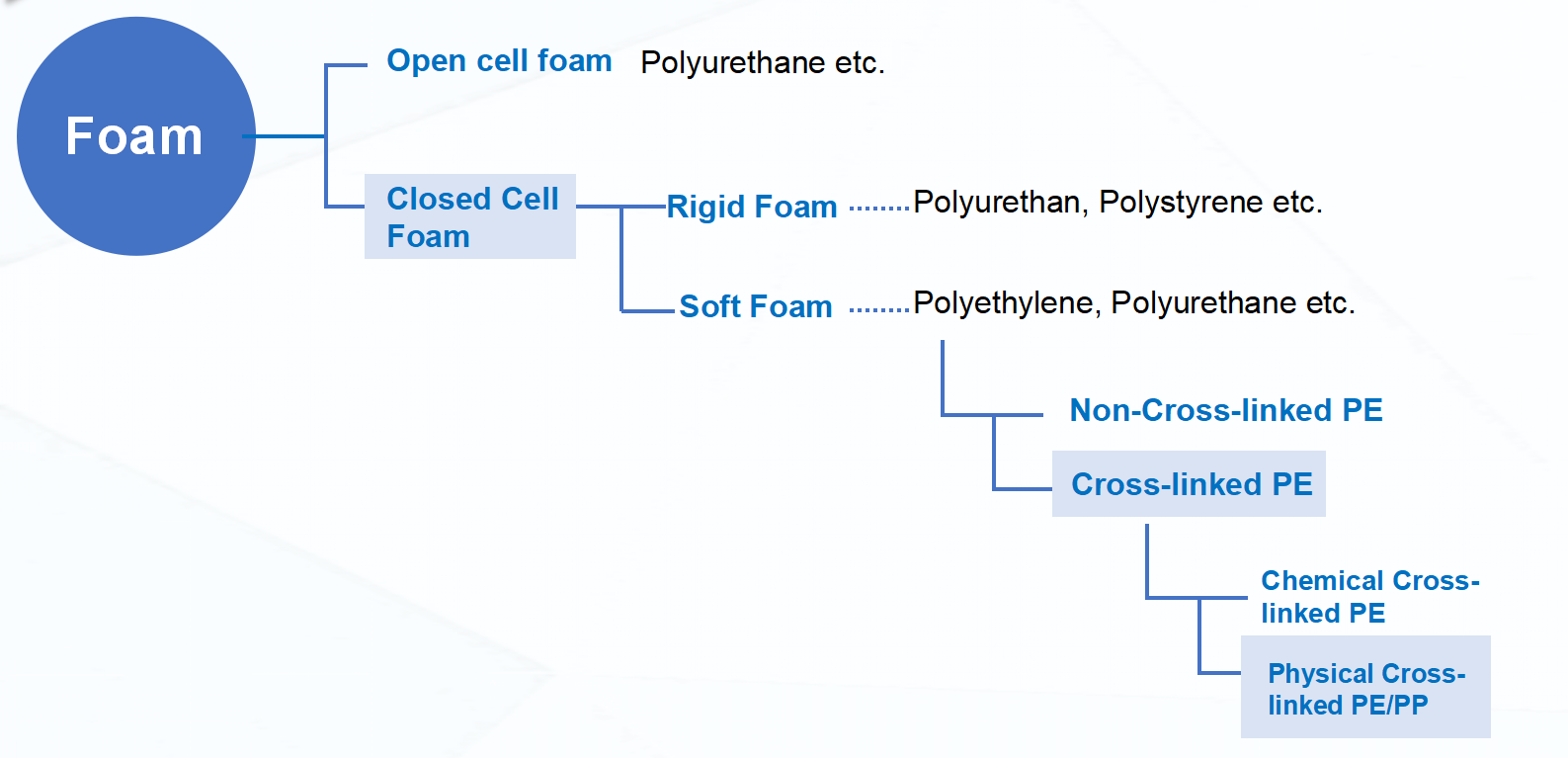

Igwebu

Igwebu wuhlobo lomkhiqizo wepulasitiki lapho amabhamuza omoya ehlakazwa khona ukuze abe nezimbotshana.Igwebu liqukethe umoya omningi ngakho-ke alisindi futhi lihle kakhulu ekubambeni nasekufakeni ukushisa.

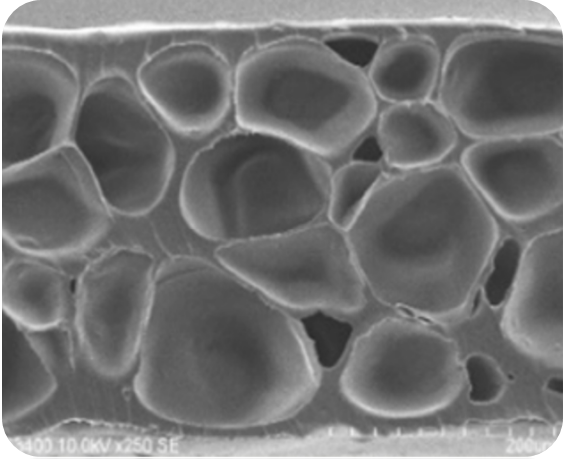

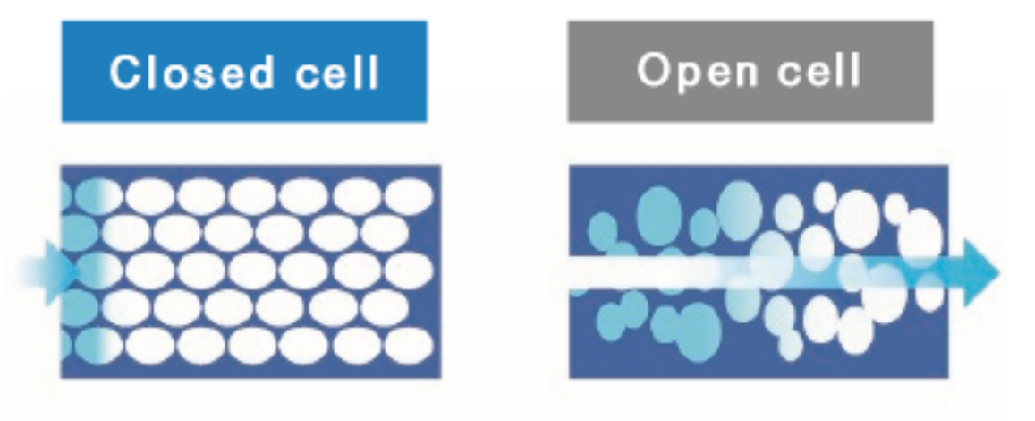

I-Closed-cell Foam

Ngaphakathi kwalolu hlobo lwegwebu, amabhamuza angaphakathi azimele, awaxhumekile komunye nomunye (iseli elivulekile).Amaseli avaliwe awawukhiphi umoya kalula.Ngakho-ke, ayaqina, alulama ngokushesha lapho ecindezelwa, futhi amelana namanzi.

I-PE ehlanganisiwe

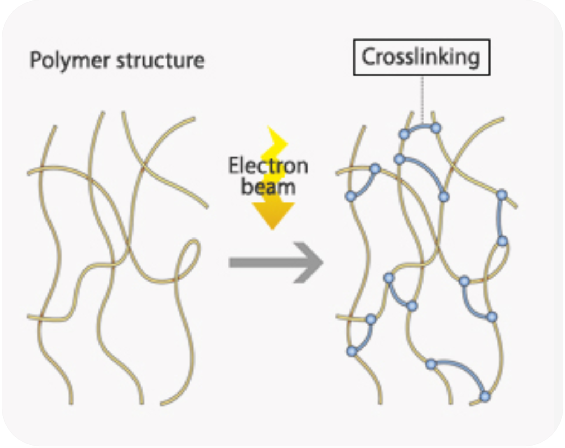

Ukusabela okuhlanganisa amaketanga e-polyethylene yamangqamuzana.Ukuphambana kwesakhiwo samangqamuzana kuthuthukisa amandla, ukumelana nokushisa, ukumelana namakhemikhali, njll. Le ndlela ibizwa ngokuthi i-crosslinking ngoba amaketanga amade amangqamuzana afana namabhuloho.

I-Physical Cross-linked PE/PP

Imishayo ye-electron iphula izibopho zamangqamuzana futhi ikhiqize izindawo ezisebenzayo ze-polymer.I-Irradiation crosslinking iyindlela yokuhlanganisa lezi zindawo ezisebenzayo kwenye nenye.Uma kuqhathaniswa nemikhiqizo exhumene ngamakhemikhali, imikhiqizo exhumene ne-irradiation izinzile futhi ixhumene ngokulinganayo.Izinzuzo zihlanganisa indawo ethambile futhi ebushelelezi futhi enhle ekuthuthukisweni kombala.

Inqubo Yokukhiqiza

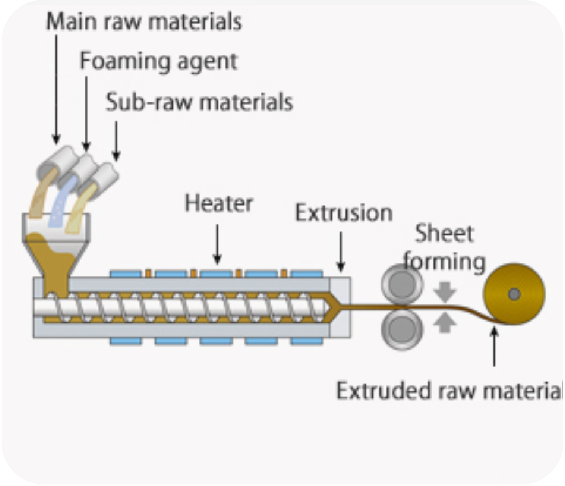

I-Extrusion

Izinto ezisetshenziswayo (i-PE/PP) zixutshwa ne-ejenti efuthayo nezinye izinto futhi zikhishwe zibe amashidi.

Ukukhipha imisebe

Ukukhipha imishayo yama-electron kuma-polymers ukuze kwakheke amabhondi eleveli yamangqamuzana.

Ukukhihliza amagwebu

Amashidi afakwe amagwebu ngokufudumeza, enze igwebu elinomthamo ofika izikhathi ezingama-40.

Ukumelana Namanzi/Amandla Okumuncwa

Ukumelana Namanzi/Ukumuncwa

Igwebu leseli elivaliwe elisekelwe ku-polyolefin limunca amanzi aphansi

Njengoba i-polyolefin iyi-lipophilic resin, iyinto ephansi ye-hygroscopicity.Amaseli ku-IXPE/PP awaxhunyiwe, angakuvumeli ukungena kwamanzi, okubonisa ukumelana kwamanzi okuhle kakhulu.

Amandla

Iqinile kodwa iyagobeka, inokumelana nokushisa okuphezulu uma iqhathaniswa namagwebu angaxhumene

Ukuxhumanisa ukwakheka kwamangqamuzana e-polymer ngamabhondi afana nezintambo eziboshelwe kuqhubeke kuqinisa izibopho zamangqamuzana, okuholela ekwakhiweni kwe-molecular lattice mesh, ukuthuthukisa ukumelana nokushisa namandla.

| I-Crosslinked | Okungaxhunywanga | |

| Isilinganiso Sokunweba | Izikhathi ezingama-30 | |

| Ubukhulu | 2 mm | |

| Amandla Okuqina (N/cm2) *2 | 43 | 55-61 |

| Ukwelulwa (%)*2 | 204 | 69-80 |

| Amandla Ezinyembezi (N/cm2)*2 | 23 | 15-19 |

| I-Max Opeing Tem*3 | 80℃ | 70℃ |

I-Thermal Conductivity I-Thermal Insulation Heat Resistance

I-Thermal Conductivity

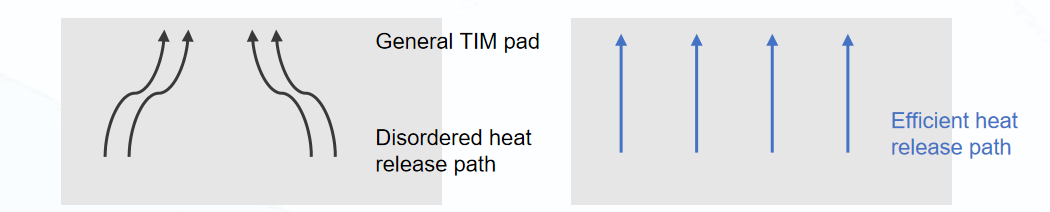

I-thermal conductive filler ehlelwe kahle ifinyelela izinga eliphezulu le-thermal conductivity

Silawula umumo we-anisotropic thermal conductive filler ukuze sakhe izindlela ezisebenzayo zokukhulula ukushisa, sithole ukuqhutshwa kwe-thermal okuphezulu nokuthambile.Ngaphezu kwalokho, ukwakheka kwethu kwempahla kwenziwa ngezinto zokuvikela zikagesi kuphela kanye nama-resin angenayo i-siloxane, okunciphisa ubungozi bokulimala kwezingxenye ze-elekthronikhi zibe sezingeni eliphansi kakhulu.

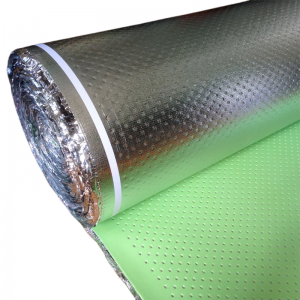

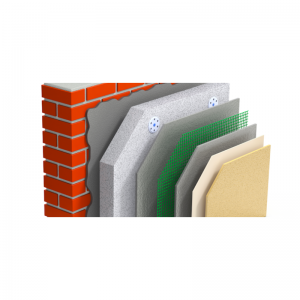

I-Thermal Insulation

Igwebu eliqukethe inani elikhulu lomoya eline-convection encishisiwe eholela ekusebenzeni okuphansi kwe-thermal kanye nokusebenza okuphezulu kokufakwa kwe-thermal

Amaseli avaliwe kugwebu akhawulela inani lokuguquguquka komoya, aqhuba ukushisa okuncane, okunikeza ukufakwa okuhle kakhulu kokushisa.Ihluke kuboya bengilazi kanye negwebu eliqinile, igwebu livumelana nezimo kakhulu futhi kulula ukulifaka.Ngakho-ke, kufanelekile kuma-insulators ukugcwalisa izikhala ezincane kakhulu ezindlini nasemishini ehlukahlukene.

Ukumelana Nokushisa

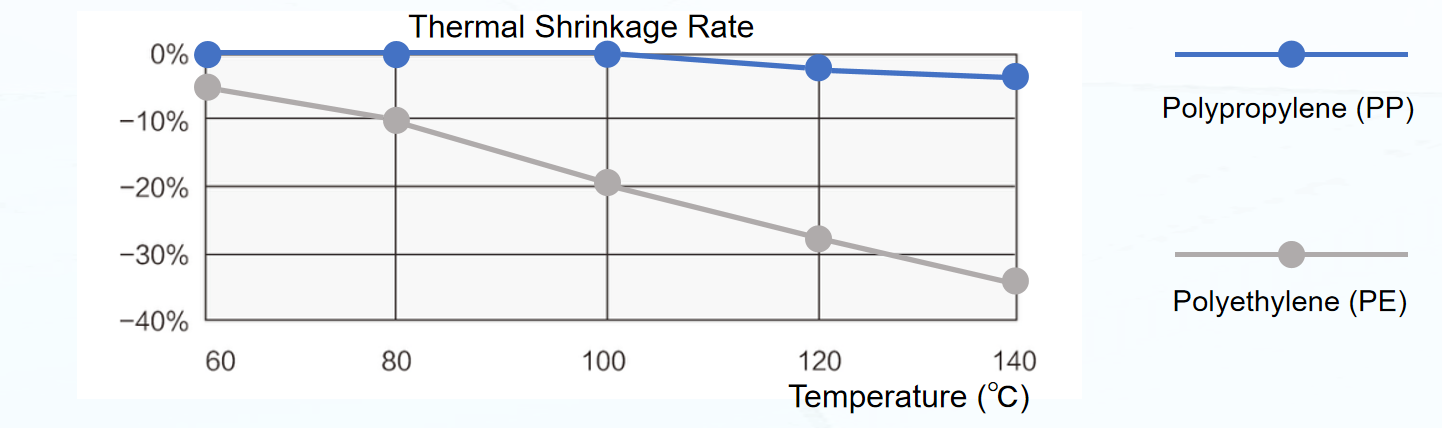

Ngokumelana nokushisa okuhle kakhulu, i-polypropylene resin inokuncipha okushisayo okushisayo ngisho nasebangeni lokushisa eliphezulu

Izinga limelela ukuthi igwebu lishintsha kangakanani ngosayizi emazingeni okushisa ahlukene lapho lishisisa ngaphandle kokusetshenziswa kwamandla angaphandle.Nakuba igwebu le-polyethylene liwohloka lapho lishisisa libe ngu-80°C noma ngaphezulu, igwebu le-polypropylene linokumelana nokushisa okuhle kakhulu ngezinga lokuncipha elingu-3% noma ngaphansi ngisho naku-140°C.

Ikhono Lokufaka uphawu Ubushelelezi Ukuguquguquka

Ikhono Lokubeka uphawu

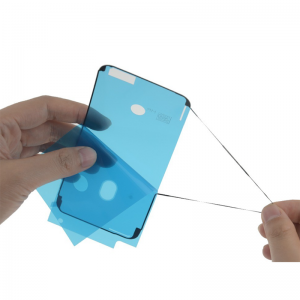

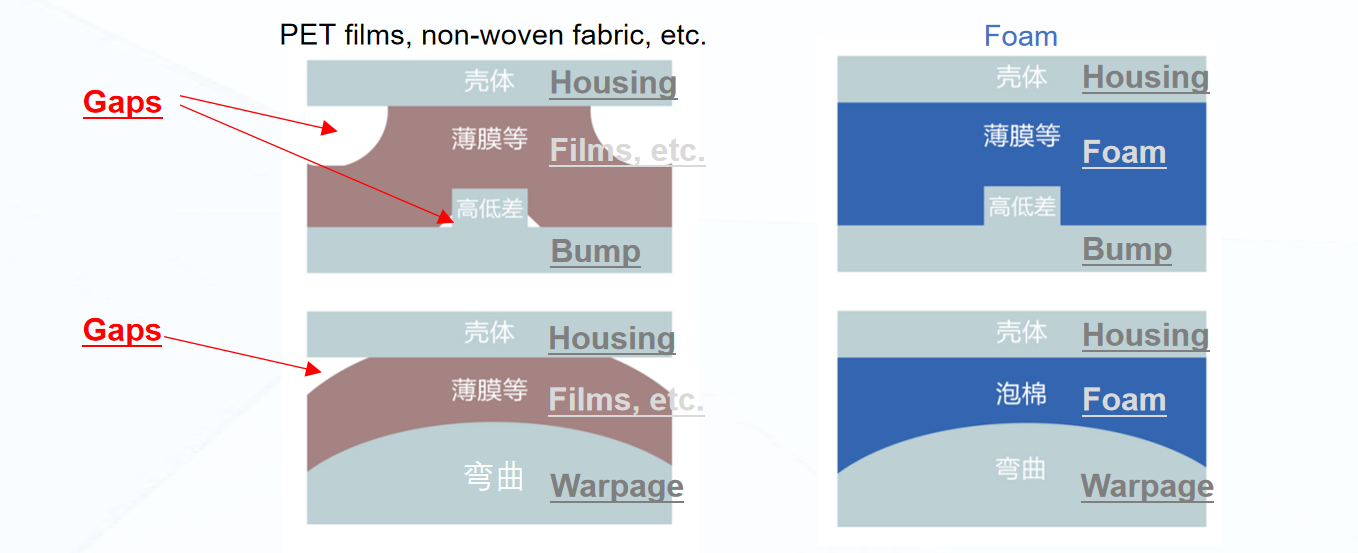

Ngokuvumelana nezimo, igwebu livala izindawo ezingalingani noma ezibukhali

Impahla yokuvala ye-sealer enjengamateyipu ayithinteki nje kuphela izakhiwo zezinto ezibonakalayo kodwa futhi ngokuthintana kwayo okuseduze nendawo engalingani ye-adherend.Into enokuguquguquka okuphezulu iqeda izikhala ngokunamathela futhi ibona ukusebenza kokuvala okuphezulu.

Qhathanisa nezinye izinto zokwakha impahla yokuvala

Igwebu livala izindawo ezingalingani futhi livale izikhala ngaphakathi kwendlu

Ubushelelezi

Indawo ethambile futhi ehlanzekile uma iqhathaniswa negwebu elixutshwe ngamakhemikhali, elifanele ukunamathela nokunamathiswa

I-electron beam crosslinking isheshisa ama-electron nge-voltage ephezulu futhi iwakhiphela kumashidi.Ama-electron e-beam angena ngokulinganayo nangokuzinza eshidini ngalinye, okuholela ekuxhumaneni okuhlangene okwengeziwe kunezinye izindlela.Ivumela ngisho negwebu elidala ungqimba olubushelelezi olufanele ukunamathela nokunamathiswa.

Ukuvumelana nezimo

Ukuthamba kwangaphakathi kwe-resin kanye nesakhiwo samaseli avaliwe kunikeza ukunwebeka nokuguquguquka okunengqondo

Iseli lamashidi e-electron-crosslinked azoqukatha i-inflate enqubweni yokukhipha amagwebu kamuva.Amaseli anezikhathi ezihlukahlukene zokunwetshwa akha isakhiwo samaseli avaliwe lapho wonke amaseli ehlukaniswa izindonga.Isakhiwo samaseli avaliwe sinokudonsa okuyingqayizivele nokumuncwa kokushaqeka.Ukuba nokumuncwa okuhle kakhulu kokushaqeka ngisho nogqinsi oluncane, amashidi e-IXPE/PP asetshenziswa njengephakeji lokucushwa kwezinsimbi ezinembayo.

Ukusebenziseka

I-Thermoformability

Umthwalo Wemvelo Ophansi

Izici zikagesi

Ukusebenziseka

Ukuqina komumo okuhle kakhulu kuqonda ukucutshungulwa okuhlukahlukene

Ngokusebenzisa i-thermoplastic polyolefin resin, igwebu lethu lingashintsha ukugcwala kwe-polymer ngokushintsha izinga lokushisa.Ngokufudumeza nokuncibilika, inganamathisela ezinye izinto noma ikhubaze igwebu.Ngokusebenzisa ngokunenzuzo ukuzinza komumo ekamelweni lokushisa, kungase futhi kusikwe kube yizimo eziyinkimbinkimbi.

Izibonelo eziyinhloko zokucubungula

● Ukusika (ukushintsha ukujiya)

● Lamination (heat welding)

● Ukusika (ukusika ngesikhunta)

●I-Thermoforming (i-vacuum forming, i-press molding, njll.)

I-Thermoformability

I-IXPP imelana namazinga okushisa aphezulu ngesikhathi sokubunjwa, ivumela ukudonseka okujulile kakhulu

I-Polypropylene (PP) inephuzu lokuncibilika eliphakeme kune-polyethylene (PE).Ngokumelana kwayo nokushisa okuhle kakhulu ngisho namazinga okushisa aphezulu ngesikhathi sokubunjwa, i-PP ingafinyelela kokubili okuhle kakhulu kwe-thermoformability kanye ne-cushioning.Ikakhulukazi, i-PP isetshenziswa kakhulu ezintweni zokwakha zangaphakathi zezimoto kanye namathreyi okuvikela izithelo.

Umthwalo Wemvelo Ophansi

I-halogen-free, awekho amagesi anobuthi lapho eshile

I-Polyolefin iwuhlobo lwepulasitiki etholwe ngokuhlanganisa ama-monomers (okungukuthi amayunithi ama-molecule) ane-carbon-carbon double bond.Njengoba ingenawo ama-halogen afana ne-fluorine ne-chlorine, ayikhiqizi amagesi anobuthi obukhulu lapho ishile.

Izici zikagesi

Inani elikhulu lomoya ngaphakathi kwamaseli avaliwe linikeza amandla amahle kakhulu e-dielectric kanye nemvume ephansi

Isakhiwo samaseli avaliwe, lapho umoya onamandla aphansi we-dielectric uvalelwe ezindaweni ezincane ezihlukanisiwe, ubonisa amandla aphezulu e-dielectric.Ngaphezu kwalokho, i-polyolefin, enemvume ephansi uma iqhathaniswa namanye amapulasitiki enhloso evamile, eyakhiwe esakhiweni esiqukethe umoya inikeza imvume ephansi ngisho nangaphezulu.